We are also called ethanol solvent low temperature ethanol extraction machine.

How Single effect ethanol recovery machine Work?

The ethanol recovery machine steam enters the outside of the column tube of the heating chamber. The material liquid is heated up. Sprayed into the evaporation chamber from the nozzle. And the vapor-liquid separation is carried out. And the material liquid returns to the lower part of the heating chamber from the circulating tube and then heated. And the material liquid is heated and sprayed into the evaporation chamber to open a cycle. The single-effect concentrator material liquid is concentrated to a certain extent.

And after sampling is determined to be qualified. It is discharged from the discharge port. And the steam evaporated from the evaporation chamber is eliminated by the defoamer and then passed through the vapor-liquid separator. Part of the material liquid returns to the evaporation chamber. And the rest of the secondary steam is cooled into a liquid by the condenser and cooler into a liquid storage barrel. And the non-condensable gas is discharged into the atmosphere or taken away by a vacuum pump.

The structure of single effect ethanol recovery machine :

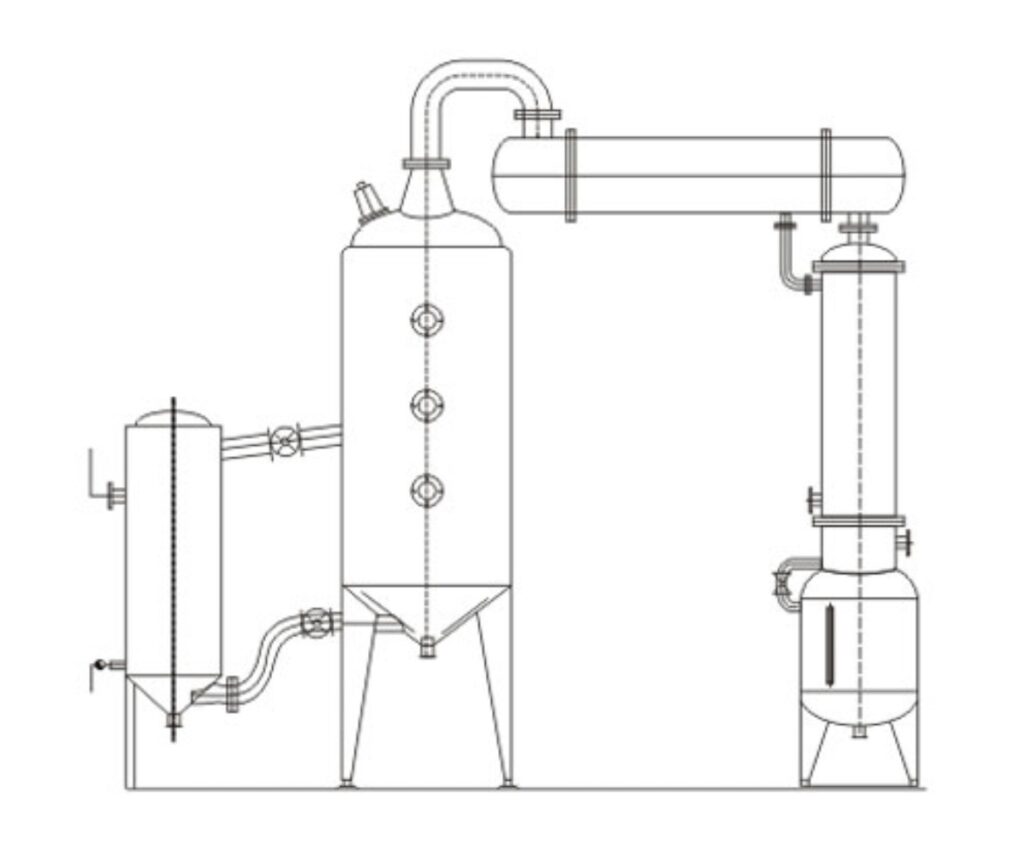

The single-effect (external circulation) concentrator ethanol recovery machine is composed of heating chamber. Evaporation chamber. Foam catcher. Condenser. Cooler. Liquid receiving tank and system inline pipe valve. supporting instruments. etc. The part in contact with the material is all made of stainless steel 304/316L. which has good corrosion resistance. Beautiful appearance. Heater. Evaporator are equipped with heat preservation. Thermal insulation external stainless steel plate to make the shell. The surface to do mirror or matte treatment. Fully meet GMP standards.

Tech drawing of the alcohol evaporation:

Manufacturing Images after installation :

The Ethanol recovery machine working in the plant video as follows/working very good at plant:

The characteristics and benefits of concentrator equipment:

1.

Alcohol recovery: The large recovery capacity. Vacuum operation method of the concentrator improve the process flow of the JN series. The recovery rate can reach 95%. So that the alcohol loss rate is less than 5%. Energy consumption is reduced by 30%. with small investment. high recovery efficiency concentrator energy-saving equipment

2.

Concentrated liquid material: this equipment adopts external heating natural circulation type and vacuum negative pressure evaporation mode, the evaporation speed is fast, the concentration specific gravity can reach 1.3; the liquid material is concentrated without foam in the fully sealed state, and the chemical liquid concentrated by this equipment has the characteristics of strong drug smell, and it is easy to clean (open the upper and lower covers of the heater to clean). This equipment is simple to operate and occupies a small footprint. The heater and evaporator adopt stainless steel insulation structure, the insulation adopts polyurethane foaming, the outer surface is matte and matte, and the concentrator meets GMP pharmaceutical standards.

3.

The heater adopts a quick opening structure, which is very convenient for workers to clean.

4.

The condenser adopts three strokes, which not only has a large condensing area, but also has a large heat exchange effect.

5.

Concentrated liquid material: this equipment adopts the combination of external heating natural circulation and vacuum negative pressure evaporation, the evaporation speed is fast, and the specific gravity of concentration can reach 1.3.

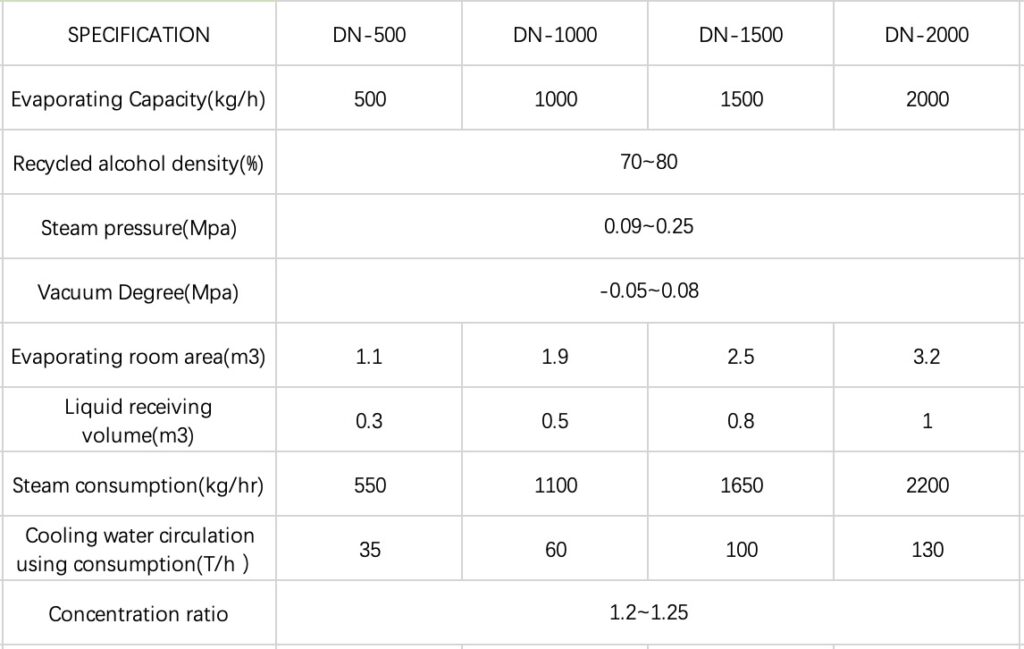

The technology parameter of the ethanol recovery machine :

We are providing Ethanol recovery machine design.engineering.manufacture.installation.staff training.

Ethanol recovery machine shipment by Ocean.

Payment:TT 50%

Packing:we are most of time send machine into container with Soft clothes. some will be put into wooden cases.important components will take care and put into cases too.

Production time:45days after tech drawing confirmed .

Material:SS316L/SS304

Place of origin: China

Video outgoing inspection: provided

Machinery test report:provided

Market type:2020

Warranty core components:1 year

Key selling point: easy operate for workers.

Type:continues

Machine type:vacuum

Condition:new

Brand:Centon

Voltage:Customized

Power:Customized

Demensions(L*W*H)customized

Name:Ethanol recovery machine

Type:multifunctional

Max temp:225

Industrial boiler :hot oil boiler

Capacity:customized

After sale service: overseas service available

FAQ:

Q:why would i choose you to customized Ethanol recovery machine?

A:we are supply and stock wide range of stainless steel products.we have active management .Experience technical people over 20 years.labor worker and high effective sales team.mass production ensure on-time delivery and quickly response to any inquiry and quote or complaint.

Q:Could I order sample order ?

A:Yes.Welcome sample order to check quality and test it.we are glad to provide you experiment machine and mixed order is ok.

Q:What is your Ethanol recovery machine production lead time??

A:Stock Sample time :1~3days. Mass production time: arround 30~45days based on your request.

Q:Did you have product warranty ?

A:Yes.We are have 12 months warranty. We are 100% inspection on finished products before dispatch.Inferior products can be returned or replaced without excuse. Repair parts could be supplied for replacement to you..

Ethanol recovery machine shipment and installation .

A:Equipment is very big so most of time we are shipment to worldwide by sea .

Q:how to installed equipment ?

A:our engineer could visit customer factory directly to help installing and training but all of cost should payment by customer.Also customer could use themself local installation team .we are also provide 12 hours picture and video service.if any problem during installation or production.Just message us our engineer will help resolve customer issue soon.